Common Lubricants Used in Chain Drives

The most effective motor control solution is the variable frequency drive or adjustable speed drive. Its simplest on a newclean drivetrain you just need to degreasecleandry the chain then wash in the hot wax.

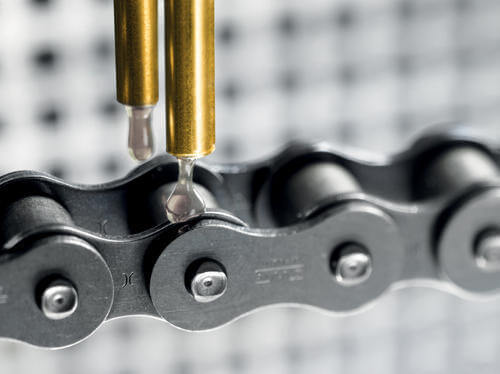

Chain Lubrication Best Practices For Drives And Conveyors

The digits in brackets belong to the system but are not used in the series designation in practice.

. A rotary-screw compressor is a type of gas compressor such as an air compressor that uses a rotary-type positive-displacement mechanismThese compressors are common in industrial applications and replace more traditional piston compressors where larger volumes of compressed gas are needed eg. This was the same casting that was used in the SOHC 40L for 97 and 98 so the cranks from both engines can be interchanged in spite of the fact that Ford gave them different part numbers. Bearing series designations consist of an identification for the bearing type and the dimension series.

DIN 51524 Part 3 HVLP Poclain HV 46 Sperry Vickers I-286-S3 M-2950-S. O-rings are a form of gasket or seal that features a round cross-section. The problem gradually reduces belt performance by increasing wear and fatigue.

The net result is excessive oil usage. Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic industrial and agricultural machinery including conveyors wire- and tube-drawing machines printing presses cars motorcycles and bicyclesIt consists of a series of short cylindrical rollers held together by side links. Wall Street closes higher boosted by tech stocks gains on upbeat earnings.

For large refrigeration cycles such as chillers or for. The three most common types of chains used for drives are. Sheave misalignment on V-belt drives should not exceed 12 deg.

Stocks ended higher on Wednesday with the tech-heavy Nasdaq booking a 16 gain on. Roadcc readers weigh in on chain lubricants. Bunker fuel is the colloquial term for fuel oil used by marine vessels.

One type of O-ring material. In a study of the efficiency of bicycle chain drives by James Spicer in 2000. Door-related problems are the most common cause for train stoppage.

This is a common warning sign of a loss of oil control. They are commonly used to prevent leaks of either fluids or gases from occurring in products systems or machinery and find use across a variety of industries. Specialty lubricants in the railway industry.

Silent inverted-tooth chain covered by ASME B292. How can you increase the reliability of train doors extend maintenance intervals and improve passenger satisfaction by using high-performance oils and greases. Electric motors are the backbone of modern automation.

Liquimatic HV 46 is particularly recommended for contractors plant and machinery. Bunker fuels A B and C are respectively downgrading quality-classifications of fuel oil characterized by their boiling points carbon-chain lengths and viscosities all of which contribute to their value in other words Bunker A is more valuable than Bunker C see Fig. Often insufficient lubrication can be the reason.

Misalignment is one of the most common causes of premature belt failure Fig. Although transportation and utility fuels dominate a large proportion of refined products essential everyday materials like wax and plastic are also dependent on crude oil. And engineering steel offset sidebar chain covered by ASME B2910.

The purpose of this paper is to identify and explore the content of Logistics and Supply Chain Management and to find the connections and the differentials factors that are between the two areas. A quick way to evaluate above-normal oil usage is to pull the spark plugs and look for oil on the threads of the spark plugs. Havent used waxed chain outside much yet but seems good so far.

Can also be used in hydrostatic drives power steering systems brake systems and other applications where products of this type and specification is required. Motors convert electrical energy into mechanical energy and the resulting motion and torque drives a load. By Echo Wang Reuters - US.

The XL2E-BA casting that was introduced in 99 was used up through 2000 when the OHV engine was discontinued. Drives vary motor input frequency and voltage to control motor speed and torque. A chain lubricant should have low enough viscosity to penetrate into.

The most common series designations are shown in table 1. Sometimes this glaze will exhibit excessive oil consumption with or without the presence of the classic blue oil smoke. Precision roller chain covered by American National Standard ASME B291.

2 for a breakdown of fuel mix types. With about 10 of refined products used to make plastics cosmetics and textiles a barrel of crude oil can produce a variety of unexpected everyday products. Depending on severity misalignment can destroy a belt in a matter of hours.

Volatilization burn-off oxidation and excessive deposit formation from. Belt tension at steady state can be calculated as66Tb137fLg2mi2mbmmcosδHgmmwhere Tb is the belt tension N f is the coefficient of friction L is the conveyer length in meter divided by two g is the acceleration due to gravity 981ms2 mi is the load of idlers within 1m length of conveyer belt kg mb is the load. Resists Oxidation and High-Temperature Breakdown Premium Protection Synthetic Motor Oil is formulated to overcome the thermal deficiencies common to conventional petroleum oils.

Best Bike Chain Lubes How To Make Your Bike Faster Quieter Smoother Bikerumor

Chain Lubrication Best Practices For Drives And Conveyors

Chain Lubrication Best Practices For Drives And Conveyors

Chain Lubrication Best Practices For Drives And Conveyors

Chain Lubrication Best Practices For Drives And Conveyors

101 Guide Understanding Chain Drive And The Need For Chain Lubrication

Comments

Post a Comment